Screening

Filtration

– Physical and chemical processes – sedimentation, coagulation

– Membrane cleaning methods – ultrafiltration

The process of settling and clarification of water with the use of thin-film modules and recycle sludge to create the contact sludge

• Excellent quality of clarified water

• Lower doses of reagents

• Low space requirements

• Reliable technology, backed by a large number of completed projects

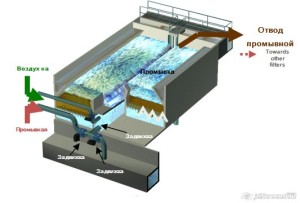

Upcoming free-flow filters

• The filter material with the same grit

– Reducing the height of filtered water over the surface of the sand (1.00 m)

– Pressure loss in order to avoid the possibility of contamination of the filter layer, caused by increased release of air from the water

- The hydraulic control system for each filter section

– Constant flow of water at the outlet of the filter due to the compensation of pressure losses that occur due to delay pollution

- Tangential flushing with raw water

– Effective removal of contaminants from the source water use

– Reducing the volume of waste water + energy

Fig. The membrane separation

Ultrafiltration – Continuous process

• Punching through a porous membrane

• Removal of suspended solids, organic matter and microorganisms

• Types: a dead-end filtration and tangential

Desalination:

• Filtration

• scavenger

• Ion exchange filters

– Counterflow

– Floating loading,

– Packed bed, air-flow,

– UFO / UPCORE

- Mixed

– Working, polishing, multistage

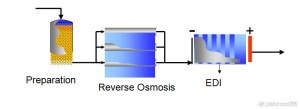

- Membrane Technology

- Reverse osmosis,

- EDI

- Ion exchange system with internal regeneration

– The efficiency of the separation and regeneration of the resins depends on

the ratio of the diameter of the filter to the height of the resin bed

– The sodium content (Na) £ 2 ppb

- External Regeneration

- – A few (1 to 4 pcs.) Of the individual filters, designed for the most efficient possible separation and regeneration of the resins

1 ppb£- The content of sodium (Na)

– Prevent possible penetration of the reagents used in the regeneration, in the condensate path through the use of additional filters regeneration

– Equipment for the regeneration and storage of reagents mounted in a room; the boiler room is not exposed to any hazards

- – A few (1 to 4 pcs.) Of the individual filters, designed for the most efficient possible separation and regeneration of the resins

Reverse Osmosis – Continuous technology

• The process of membrane separation

• The push by pressure through a semipermeable membrane

• Removal of salts, organic matter and microorganisms

• Type: tangential filtration

Electrodeionisation — EDI – RFIC technology – Continuous operation

• High quality treated water

• Small space requirements

• Minimum costs for automation

• Lack of wastewater contaminated reagents

– Cation exchangerCondensate’s cleaning

• Carbon filters

• Anthracite filters

• Cartridge filters

• Ion exchange

– FSD anion exchanger with internal and external regeneration

– Filter ion exchange technology Multi-step exchanger

– Air-conditioning systems using reagents

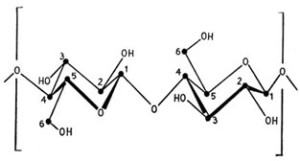

The structure of Cellulose – Filter